Letterpress printing is a traditional technique that dates back to the 15th century, and it still remains a favourite among designers and printing enthusiasts today. Known for its tactile quality and elegant results, letterpress printing adds a unique, handcrafted touch to various printed materials.

Letterpress printing was invented by Johannes Gutenberg in the mid-1400s. This revolutionary method involved arranging movable type, inking it, and pressing it onto paper. Gutenberg’s invention made it possible to produce books and documents more efficiently, paving the way for the spread of knowledge and the growth of the printing industry. Over the centuries, letterpress printing evolved, incorporating new technologies and techniques, but its fundamental principles have remained largely unchanged.

The Basics of Letterpress Printing

At its core, letterpress printing involves creating a raised image on a surface, inking that image, and pressing it onto paper or another substrate to produce a print. The process relies on three main components: the press, the type, and the ink.

- The Press

The press is the machine used to apply pressure to the type, transferring the inked image onto the paper. There are several types of letterpress machines, including platen presses, cylinder presses, and flatbed presses. Each type has its unique characteristics and is suited to different kinds of projects. - The Type

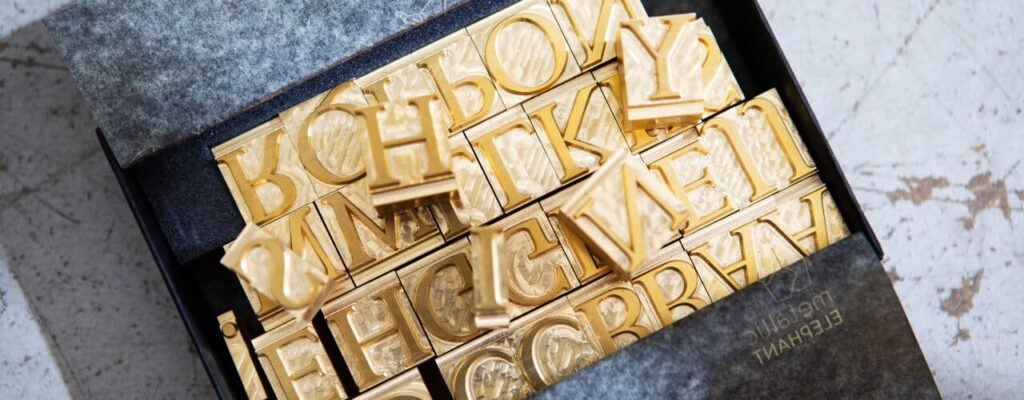

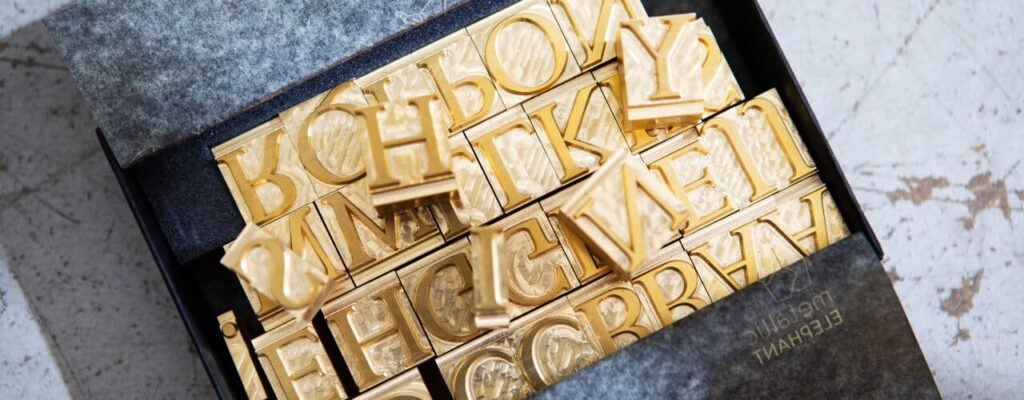

The type consists of individual letters, numbers, and symbols that are arranged to form the desired text or image. Traditional letterpress printing uses metal or wooden type, but modern letterpress printers often use photopolymer plates, which are created using digital designs. These plates offer greater flexibility and precision, allowing for more intricate designs and faster setup times. - The Ink

Letterpress ink is typically a thick, viscous substance applied to the raised surface of the type or plate. It can be oil-based or rubber-based, each offering different drying times and finishes. Printers must carefully select the right ink for their specific project to achieve the desired results.

How Letterpress Printing Works

Letterpress printing involves several steps that require precision and craftsmanship to achieve the desired results. The process begins with the creation of a design, which can be done by hand or using digital design software. The design must be tailored to the specifics of letterpress printing, emphasising solid, bold lines that can handle the pressure and ink. Once the design is finalised, it’s transferred onto a photopolymer plate or assembled using metal or wooden type. Photopolymer plates are created using a UV light exposure process that hardens the design areas, leaving the non-design areas soft and removable. The traditional type involves arranging individual letters and symbols by hand.

The next step is inking the raised surface of the plate or type. This is done using an ink disk or rollers that apply a consistent layer of ink across the surface. The ink must be evenly distributed to ensure a high-quality print without smudges or gaps. The inked plate or type is then set up in the press. The paper is positioned in the press, and the press is operated to apply pressure. This pressure transfers the inked design from the plate or type onto the paper. The amount of pressure must be carefully calibrated to achieve a deep, crisp impression without damaging the paper.

Each sheet of paper is fed into the press individually, and the process is repeated for each print. For designs with multiple colours, the paper must go through the press multiple times, with precise alignment, to ensure the colours register correctly. After printing, the prints need time to dry. The drying time can vary based on the type of ink and environmental conditions. Once dry, prints may undergo additional finishing processes such as trimming, scoring, or folding to achieve the final desired look.

How is Letterpress Printing being used?

Letterpress printing is known for its versatility and ability to produce high-quality, tactile prints. It is commonly used for wedding invitations, business cards, stationery, book covers, and art prints. The deep impression and rich texture of letterpress prints make them highly desirable for projects that require a touch of elegance and craftsmanship. Additionally, letterpress printing is favoured for its ability to create limited edition prints and custom designs that stand out from the crowd.

In the label industry, letterpress printing is used for producing high-value, short-run labels, especially for wine, spirits, and cosmetics. The trend towards shorter print runs has created a niche market for letterpress technology, allowing for complex in-line multi-process printing, embellishing, and conversion. This makes letterpress an ideal choice for labels that require intricate designs and high-quality finishes.

Embrace the Timeless Charm of Letterpress Printing

At Metallic Elephant, we produce high-quality 0.95mm and 1.52mm foil-backed polymer plates in-house. Our polymer plates are transparent for easy registration and more efficient on press due to their superior long-run capabilities. Compatible with most letterpress machines, they can hold the finest details and are robust enough for embossing or debossing.

For traditional options, we offer magnesium letterpress plates, both mounted and unmounted. These plates remain crisp and sharp, ensuring fine or bold detailing every time. Visit our website to see our artwork supply guidelines or place an order for same-day turnaround if ordered before midday.