Foil stamping is a process that produces an impressive aesthetic effect – a metallic finish in your chosen design, on a specifically selected surface. You’ll see foil stamping widely used on packaging, business cards and greeting cards, for example. It can be an indicator of luxury and quality and is a great way to differentiate products on the shelf, as it has a tangible quality and attracts the eye of consumers. So, it’s a very popular choice, but how does it actually work?

Die etching is the first stage in the process

Whatever the design you’re looking to achieve with foil stamping, it will be the die that ensures you get the result that you want. Designs are created as a vector image, which can be scaled to any size without loss of resolution. Dies made from magnesium, brass or copper are then etched with the chosen design. Magnesium tends to be the cheapest option for dies and is ideal for shorter print runs. However, if there is going to be a longer print run involved then copper or brass will be more hard-wearing. Copper is especially well suited to jobs that are very detailed or where fonts are thin.

Choosing the foils for the final aesthetic

Once you have a die then it’s time to pick the look that you want for the finished aesthetic. There are many different foils to choose from when it comes to foil stamping, not just the traditional shiny gold, silver or bronze. The choice of foil will also depend on the design – for example, easy-release foils are ideal for larger, solid areas where there is a need for a lot of coverage. As well as a broad range of foil colours you’ll also be able to choose from finishes such as fluorescent, pearlescent, gloss, matt, and patterned foils among many others.

Pick your paper or card

If you’re opting for foil stamping then you have many options when it comes to the material that you want to create your design on. Foil stamping is an opaque effect so you can apply it to any coloured card stock, for example. Light foil colours work on dark backgrounds and the technique of debossing can help your designs to pop even more. If you’re keen to create designs that make an impact, hot foil stamping is the ideal way to do it.

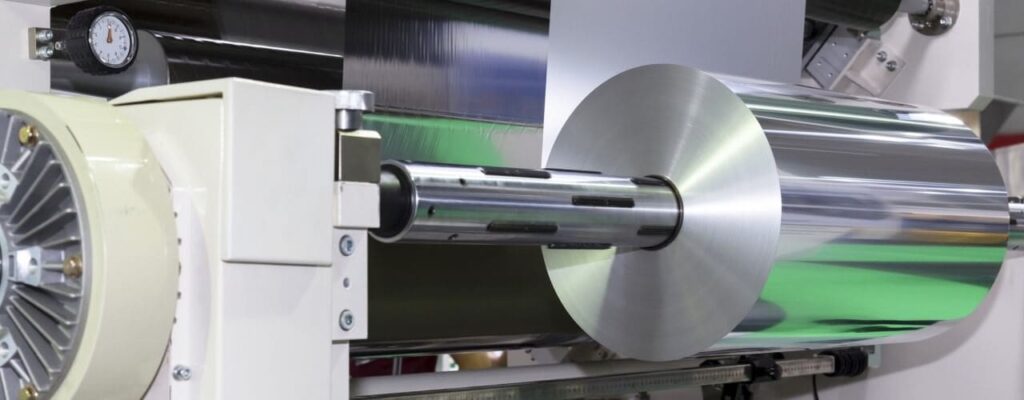

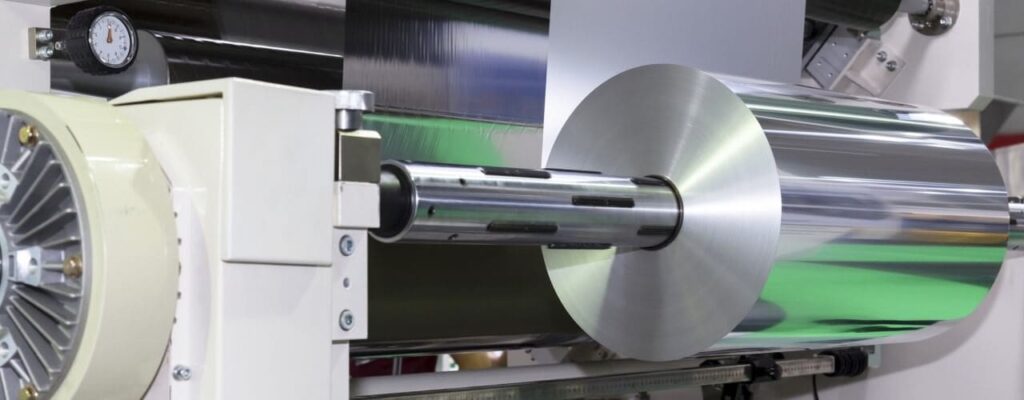

The foil stamping process

The specially created die is heated to the right temperature and then applied to the foil and the paper or card that you’ve chosen. A combination of pressure (the ‘stamping’) and heat work to ensure that your final design looks precise and detailed. The process of hot foil stamping can be repeated many times, whether you’re using it on letterheads, business cards, invitations or note cards and you will always get a consistently impressive result.

Foil stamping is actually a very simple process – once you have your dies and your foil and paper choices you have everything you need to create beautiful, detailed designs.

We design and supply a range of top-quality hot foil machines that can breathe life into your designs! Get in touch with a member of the team today to see how we can help you achieve your hot foiling dreams.